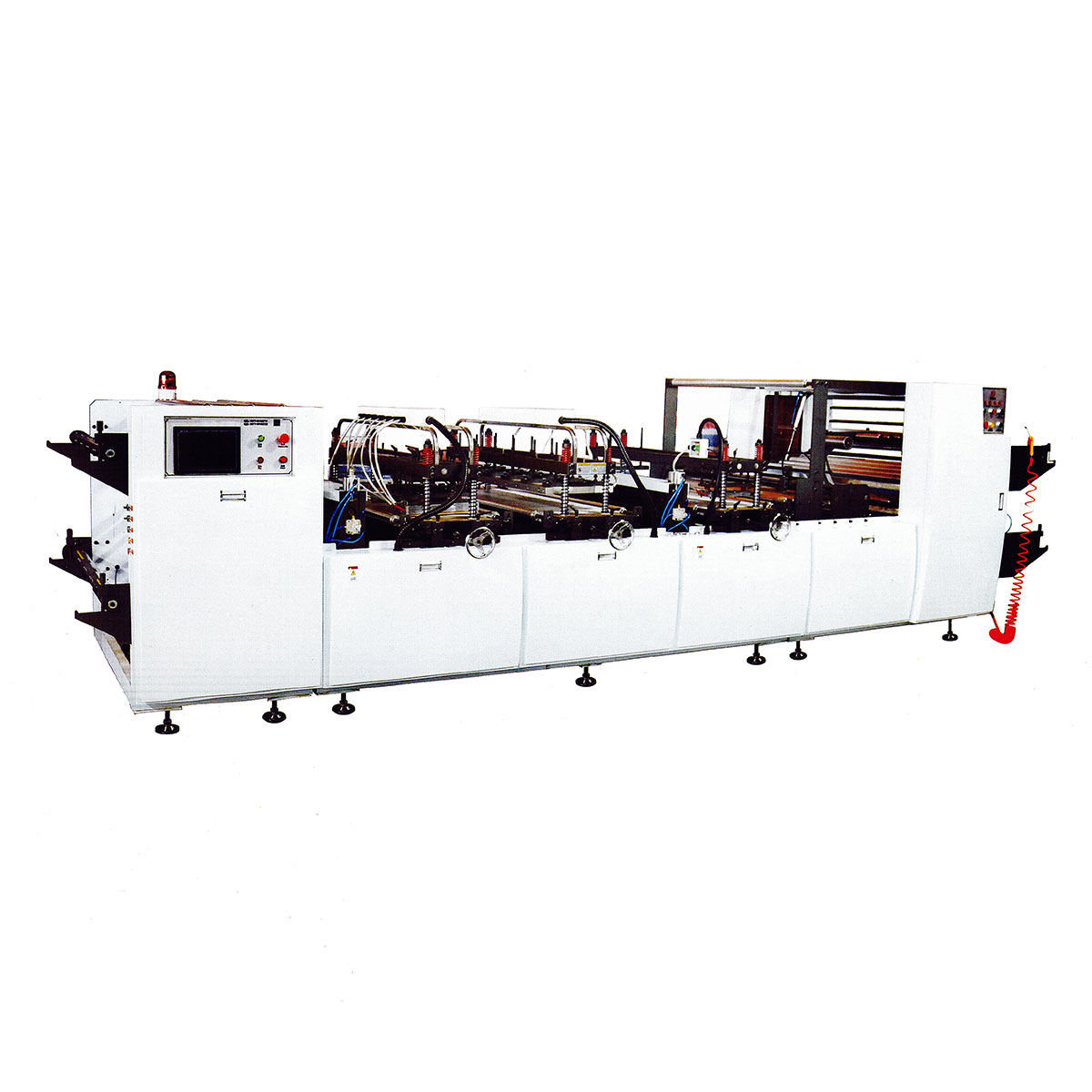

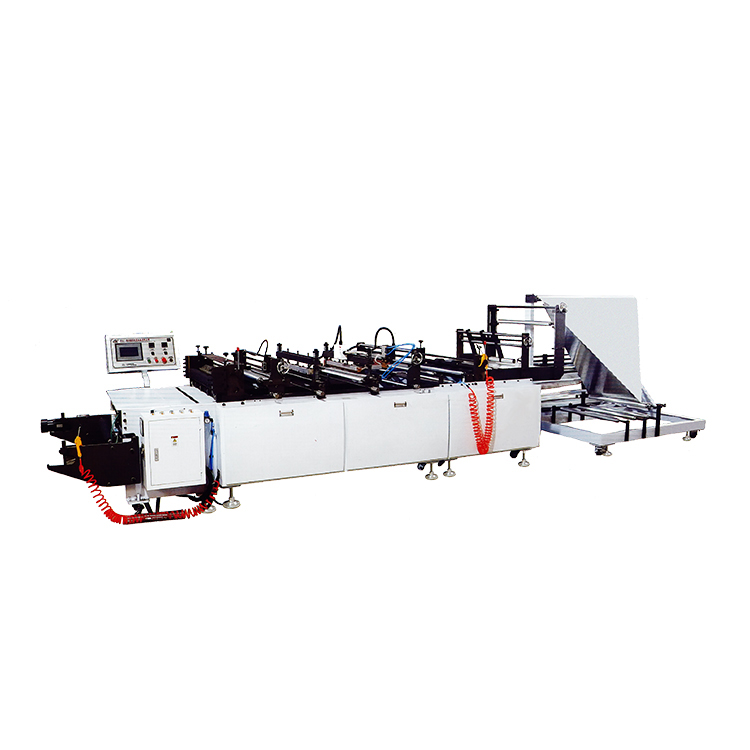

QZR1200 is a mechanical designed production line according to customer and market demand, with all the advanced technology which suitable for making all kinds of air bag, cushion bag, filling bag by PE Co-extruded film. The products are having the advantages of low cost, saving space, re-cycling, easy packing, manpower saving, no pollution and long time airtight for stock and transportation. Widely used in all kinds of packing industries, such like electronic, ceramic, furniture,lights, toner, wine, milk powder etc fragile, precision and luxurious products; also widely used in express and logistics industries.

Features

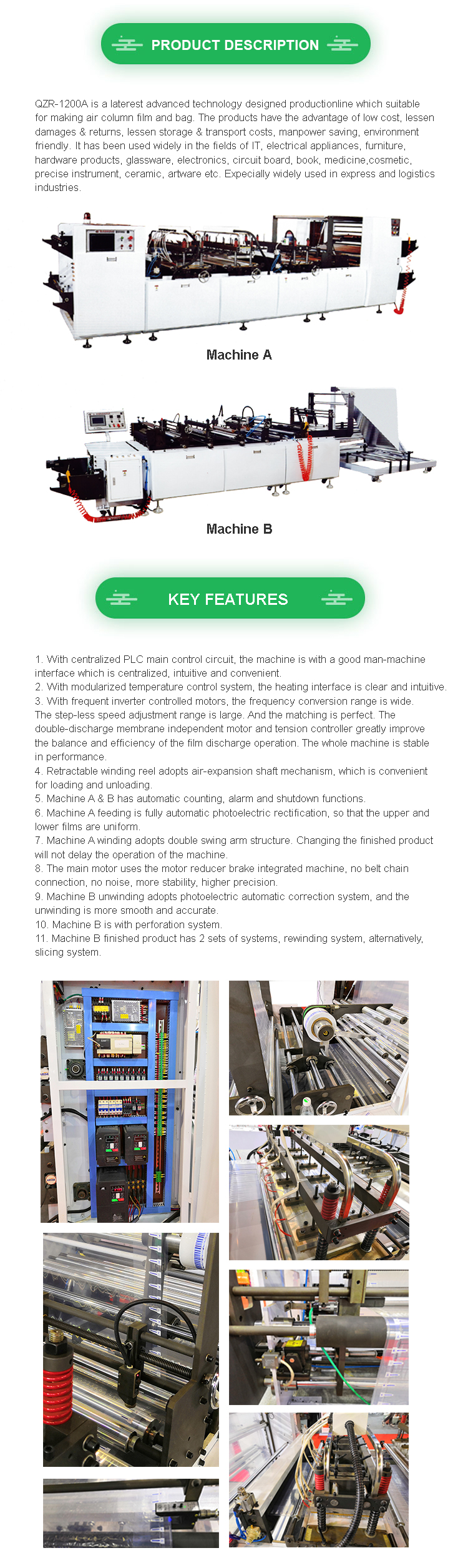

- With centralized PLC main control circuit, the machine is with a good man-machine interfacewhich is centralized, intuitive and convenient.

- With modularizedtemperature control system, the heating interface is clear and intuitive.

- Withtransducer controlled motors, the frequency conversion range is wide. The steplessspeed adjustment range is large. And the matching is perfect. The double-discharge membrane independent motor and tension controller greatly improve the balance and efficiency of the film discharge operation. The whole machine is stable in performance.

- Retractable winding reel adopts air-expansion shaft mechanism, which is convenient for loading and unloading.

- Machine A & B has automatic counting, alarm and shutdown functions

- Machine A feeding belt is fully automatic rectification and discharging, so that the

upper and lower films are uniform.

- Machine A adopts double swing arm structure.Changing the finished product will not delay the operation of the machine.

- Winding and unwinding system adopts high-performance linear displacement sensor to continuously feed and stabilize discharge.

- The main motor uses the motor reducer brake integrated machine, no belt chain

connection, no noise, stability, higher precision

- Machine B unwinding adopts photoelectric automatic correction system, and the unwinding is more smooth and accurate.

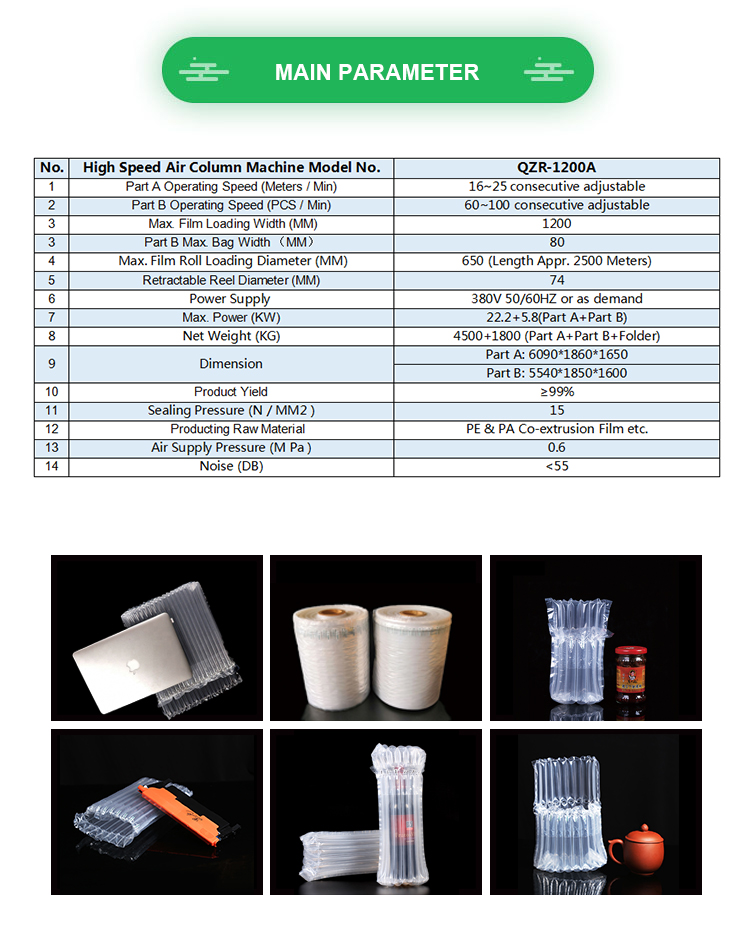

PARAMETER

| Model | QZR1200 |

| Part A Operating Speed (Meters / Min) | 12~20 consecutive adjustable |

| Part B Operating Speed (Meters / Min) | 40~75 consecutive adjustable |

| Max. Film Loading Width (MM) | 1200 |

| Part B Max. Bag Width (MM) | 800 |

| Max. Film Roll Loading Diameter (MM) | 650 (Length Appr. 2000 Meters) |

| Retractable Reel Diameter (MM) | 74 |

| Power Supply | 3 phases 380V 50/60HZ |

| Max. Power (KW) | 22.2+5.8 (Part A+Part B) |

| Dimension (L*W*H) (MM) | Part A: 6090*1860*1650 |

| Part B: 5540*1850*1600 | |

| Net Weight (KG) | 4500+1800 (Part A+Part B) |

| Noise (DB) | <55 |

| Product Yield | ≥99% |

| Sealing Pressure (N / MM2 ) | 15 |

| Producing Raw Material | PE & PA Co-extrusion Film etc. |

| Air Pressure (M pa ) | 0.68 |