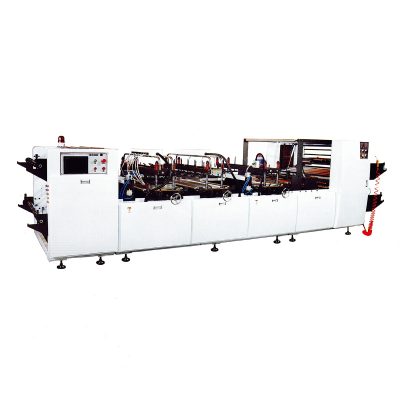

CFH-840 is a latest advanced technology designed production line which suitable for making air cushion filler and air cushion wrapper such as 20×10 20*12 20*15 20*20 CM air pillow film, 42 MM bubble in a row film, 4 tubes and 2 tubes in a row film. The products have the advantage of low cost, lessen damages & returns, lessen storage & transport costs, manpower saving, environment friendly. It has been used widely in the fields of luggage, handbags, liquid product, electronics, circuit board, book, medicine,cosmetic, instrument, ceramic, art ware, household electrical appliances, furniture, hardware products, glass-work etc.

Main feature:

- With centralized PLC main control circuit, the machine is with a good man-machine interface, intuitive and convenient.

- With modulized temperature control system, the heating interface is clear and intuitive

- With inverter controlled motors, the frequency conversion range is wide. The speed adjustment range is large. And the matching is perfect.

- Winding and unwinding systems adopts high-performance linear displacement sensor to continuously feed and stabilize discharge.

- Integrated main motor reducer brake, no belt chain connection, no noise, greatly improves stability, higher precision as well.

- Photoelectric automatic correction unwinding system, makes sure the unwinding is more

smooth and accurate.

- The parameters are attachedas below:

| CFH-840 Standard Configuration Basic Technical Parameter | |

| Operating Speed (PCS / Min) | 300-1200 consecutive adjustable |

| Max. Film Loading Width (MM) | 800 |

| Max. Film Roll Loading Diameter (MM) | 500 |

| Max. Bag Width (MM) | 800 |

| 2 Rolls At A Time | YES |

| Retractable Reel Diameter (MM) | 48 |

| Power Supply | 380V 50/60HZ |

| Max. Power (KW) | 12 |

| Net Weight (KG) | 1800 |

| Dimension | L4600*W1270*H1500 |

| Product Yield | ≥99% |

| Sealing Pressure (N / MM2 ) | 15 |

| Raw Material | PE / PE+PA Co-extrusion Film |

| Air Supply Pressure (M Pa ) | 0.68 |

| Noise (DB) | <55 |